3.14.1.3 The soiled linen area shall be kept under negative pressure

relative to the clean linen area and other surrounding areas at all times.

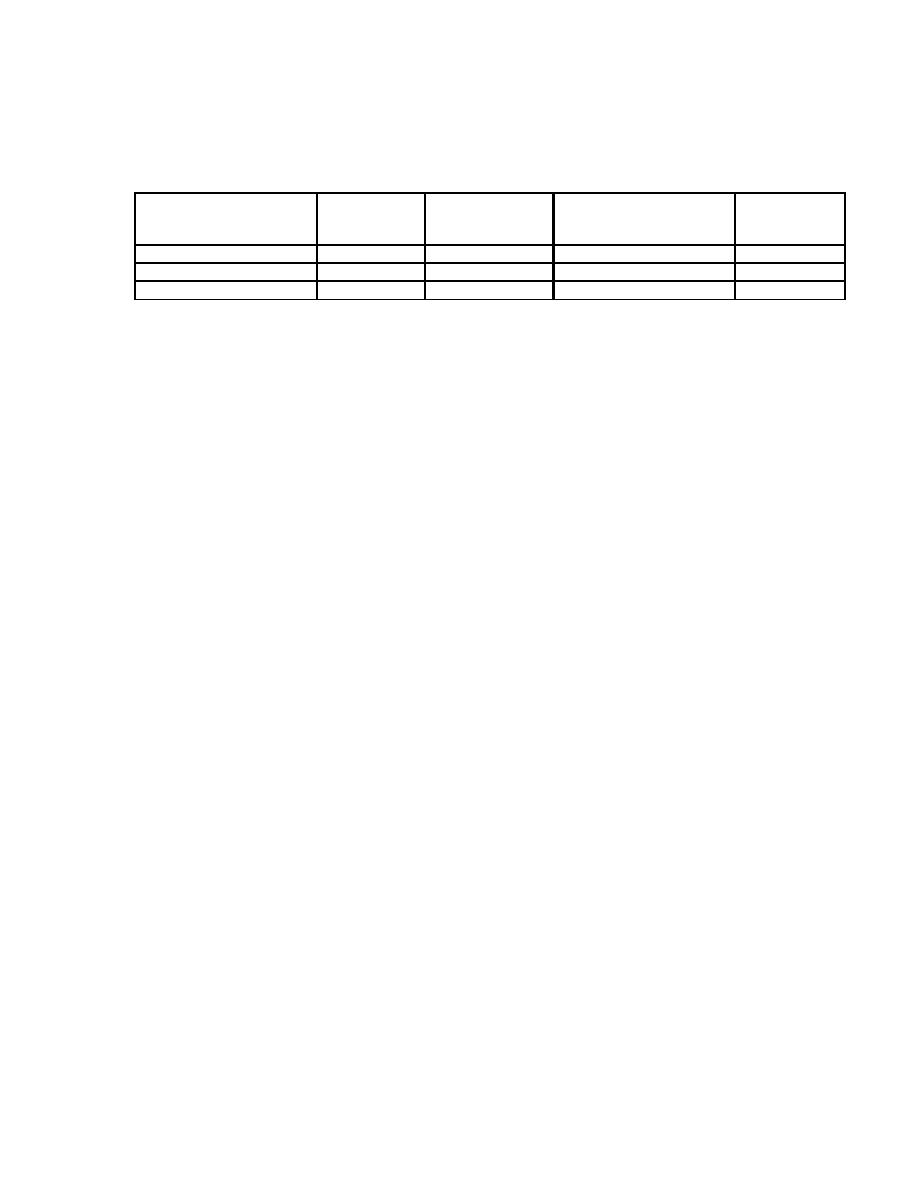

Table 3-1 Ventilation Requirements for Laundry

All Air

Minimum Air

Area

Pressure

Minimum

Exhausted

Changes/Hr of

Outdoor Air

Supply Air

Changes/Hr

Laundry, General

Negative

2

10

Yes

Soiled Linen

Negative

-

10

Yes

Clean Linen

Positive

-

2

No

3.14.2 ENERGY CONSERVATION

(a) Use a lint filter and make-up air systems to clean and recirculate the

hot dryer exhaust air back to the dryer utilizing the dryer blower.

(b) Provide heat recovery systems, wherever feasible, for maximum energy

conservation.

(c) Air change rate may be reduced during heating and cooling seasons.

(d) Insulate heat-producing equipment, where practical, to reduce the

temperature in occupied areas.

3.14.3 COORDINATION

Coordinate utility requirements and heat gain from the actual equipment

submittals with HVAC calculations for the laundry.

3.15 LINEAR ACCELERATORS

3.15.1 INDOOR DESIGN CONDITIONS

Summer: 24 degrees C (76 degrees F) Db, 50 percent RH

Winter: 25 degrees C (78 degrees F) Db, 30 percent RH

3.15.2 EMERGENCY POWER REQUIREMENTS

Closed loop water chilling equipment for Linear Accelerators shall be on

emergency power.

3.15.3 SPECIFIC REQUIREMENTS

requirements vary with the make of the linear accelerators. Check with the

equipment manufacturer for cooling requirements.

(a) The heat dissipated to the space during idle and working cycles of the

linear accelerator.

(b) The amount of internal cooling required for the equipment.

(c) The cooling shall be provided by circulating cold water at 551 kPa (80

Psig) (maximum inlet pressure) and at an inlet temperature between 10 to

29 degrees C (50 to 86 degrees F). Use closed-loop, dedicated air-cooled

chiller for supplying the water. The use of the city water is not

permitted. See Article 2.12.9 for the dedicated refrigeration system.

HVAC DESIGN MANUAL

3-12

HVAC REQUIREMENTS FOR OCCUPIED AREAS

Previous Page

Previous Page