(h) Air Distribution:

(1) The main supply air ductwork shall be sized to deliver the supply

air fan capacity, 612 Cu M/Min (21,840 CFM) as calculated in the

example above.

(2) The individual room air distribution system including supply,

return, exhaust air ductwork, air terminal units, reheat coils and air

outlets/inlets shall be sized and selected on the basis of the adjusted

supply air volume, 588 Cu M/Min (21,000 CFM).

(3) The fan and motor selection shall be based on the supply air fan

capacity and static pressure adjusted, as necessary, for the altitude,

temperature, fan inlet and discharge conditions, and the AMCA 201

System Effect Factors. The fan selection shall be made within a stable

range of operation at an optimum static efficiency. The fan motor W

(BHP), required at the operating point on the fan curves, shall be

increased by 10 percent for drive losses and field conditions to

determine the fan motor horsepower. The fan motor shall be selected

within the rated nameplate capacity and without relying upon NEMA

Standard Service Factor. See VA Standard Detail 15000-50 for the energy

efficient motors.

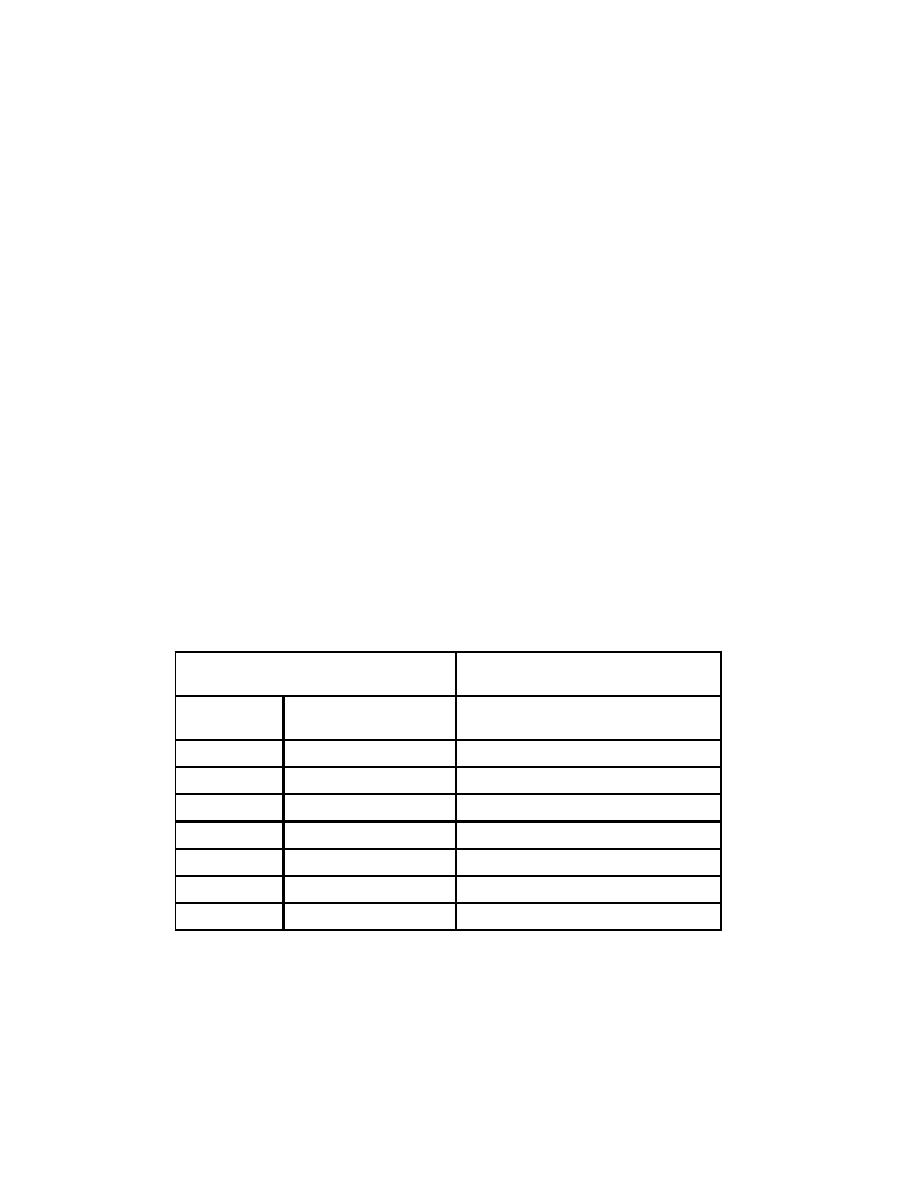

(g) Motor Voltages:

(1) Motor Voltages shall conform to NEMA/ANSI standard as follows:

Table 1-5 System/Motor Voltages

System Voltage (Transformers)

Utilization Voltage

(Motors)

Nominal

With 4 Percent

Standard (For Schedule)

Drop

120

115.2

115

208

199.7

200

240

230.4

230

480

460.8

460

600

576.0

575

2400

--

2300

4160

--

4000

1.3.15.2 CHILLED WATER SYSTEMS

(a) The capacity of the chilled water system, which consists of

condenser and chilled water pumps, cooling tower, piping, etc. shall be

based on the sum of the total cooling requirements of all connected air

handling units. See paragraph 1.3.15.1 for the derivation of the total

cooling load requirements for air handling units. No additional safety

factors should be required.

HVAC DESIGN MANUAL

1-17

GENERAL REQUIREMENTS

Previous Page

Previous Page